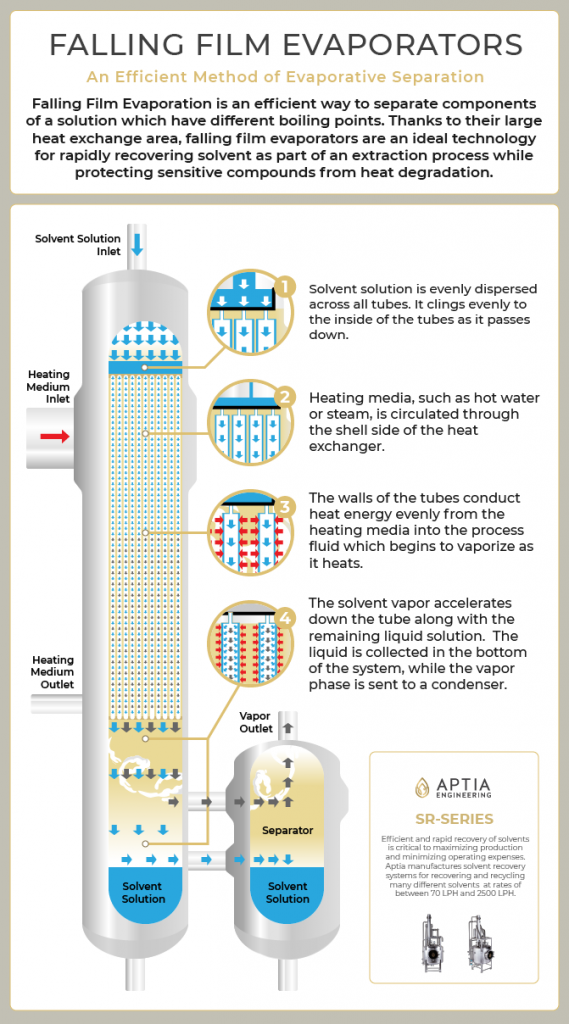

How Falling Film Works

A falling film evaporator (FFE) is a specific type of vertically oriented shell and tube (S&T) heat exchanger that is used to separate two or more substances with different boiling point temperatures.

A shell and tube heat exchanger is divided into two compartments. It’s most basic function is to bring a heating or cooling fluid, called media, into indirect but intimate contact with a product fluid, called the process fluid. Energy, as heat, is transferred rapidly and efficiently across a shell & tube heat exchanger between the media and process fluids. When the goal is to use an S&T heat exchanger to evaporate a component of the process fluid, then the media is hotter than the process fluid, and energy is transferred into the process liquid from the media.

In the specific case of the falling film evaporator, the heating media is circulated through the shell side of the S&T heat exchanger. The process fluid is passed through the tube side of the evaporator. Energy is transferred from the heating media into the product, and a portion of the product is vaporized.

The process liquid is pumped into the top of the falling film evaporator and is distributed evenly across all of the heating tubes in the heat exchanger. It is very important that the liquid be well distributed so that it evenly flows down the inside walls of each tube. This film of liquid that is descending through the tubes is known as a “falling film” and is where this particular heat exchanger derives its name.

Why Falling Film

A falling film evaporator can be an extremely efficient and effective type of heat exchanger. In fact, many factories across most major industries have been steadily updating their equipment from older rising film evaporators, calandria style evaporators, or forced circulation style evaporators to falling film evaporators due to the excellent thermal performance of a well-designed FFE.

Falling film evaporators achieve their high thermal performance via the creation and maintenance of a very thin-film of rapidly descending liquid that is laminated to the interior surface of the evaporation tubes. An evenly distributed liquid film maximizes the contact between the process liquid and the heating media, and allows for the greatest rate of energy transfer from the media to the process fluid. This means faster evaporation rates and the ability to use cooler heating media, which has benefits when handling products subject to thermal degradation.

In order to achieve this high level of performance, the descending liquid must be well distributed between all of the tubes, uniformly spread around the circumference of each tube, well laminated to the interior surface of each tube, and must travel with optimum velocity down each tube. Tubes that are not properly wetted can cause degradation of thermally labile products, are the most common cause of fouled evaporators, and have very low thermal performance.

Aptia Engineering optimizes their flow lamination system for each and every FFE that Aptia engineers and manufactures. Aptia recognizes that different applications may have a unique combination of characteristics, such as solids content, extract content, desired (%) reduction in solvent, and vapor velocity that need to be accounted for when optimizing the flow lamination system. The result is a compact FFE with superior throughput that is resistant to fouling and provides uniform, controlled evaporation temperatures.

In the hemp industry in particular, many different interpretations of falling film evaporators are rapidly increasing in popularity. The performance and reliability of an FFE ranges wildly depending upon the actual engineering aptitude of the designer. Aptia Engineering prides itself in providing high-performance equipment that has been fully engineered, diligently manufactured, and proven in practice.

Visual Diagram