Chill and Grow

Over the last several decades, hydroponics has become an efficient and profitable growing solution for all climates and operation sizes. A vast range of hydroponic setups are achievable in dense urban cities, rural areas, and previously un-growable zones. One of the most important pieces of equipment for these hydroponic setups is the reservoir chiller. Hydroponic solution chillers can vastly improve overall plant health, crop output, and profitability. Let’s walk through the process of hydroponic reservoir chilling and the essential qualities needed in a hydroponic chiller.

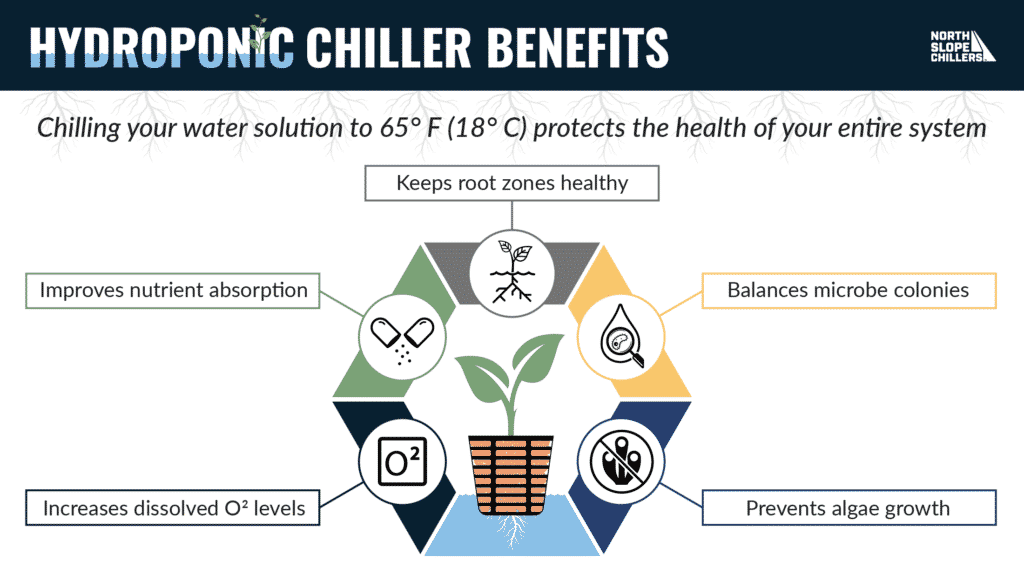

Why are Hydroponic Chillers So Important?

Successful hydroponic gardens neutralize the environmental extremes that one experiences with soil gardening and provide healthy and stable growing conditions. Air temperature, humidity, nutrient concentrations, and water solution temperatures should remain constant. Therefore, properly chilling your water solution reservoir is not a luxury, it is a necessity. Ideally, reservoirs should be kept cooler than the ambient air temperature (around 65° F/18° C).

Chilling Protects Water Solution Health

A hydroponic plant is only as healthy as its roots. Chilling your reservoir to 65° F provides the ideal environment for your root zones to thrive in a number of ways.

Overall Root Health

Hydroponic growing gives gardeners a chance to monitor a critical section of the plant that was previously hidden from view…the root zones. Plant roots need to be permeable enough to absorb everything the plant needs to grow. In addition, the environment surrounding the roots needs to be carefully cultivated to ensure plants don’t absorb harmful substances such as fungi. Chilling the water solution reservoir improves overall root zone health and keeps harmful environmental contaminants at bay.

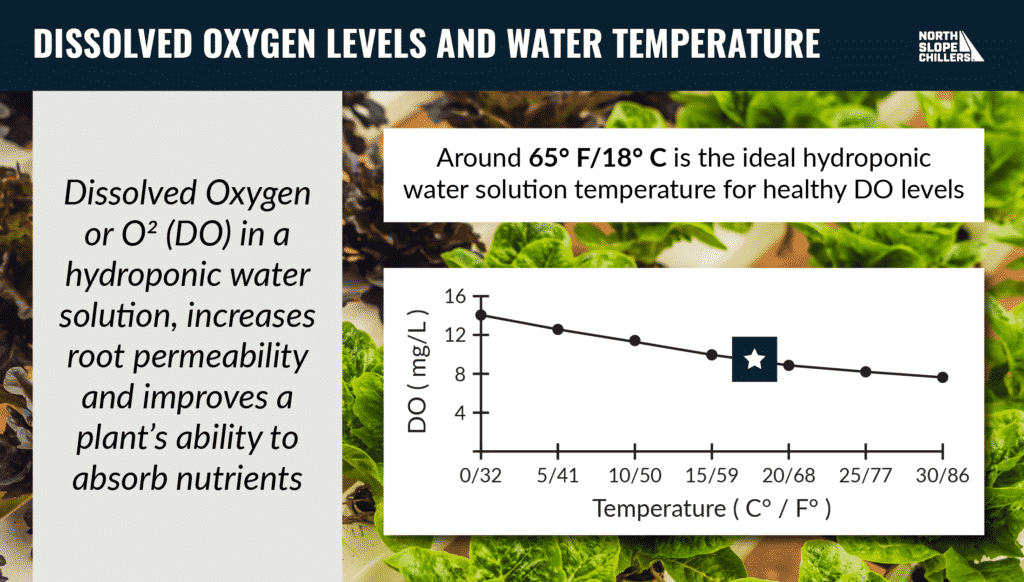

Dissolved Oxygen Levels

Dissolved oxygen (DO) is essential for a healthy root system. Aerobic respiration keeps your roots permeable and more able to absorb nutrients. DO also encourages healthy bacteria growth around the root zones, which protects your plants from fungal infections.

Using an air pump and air stone to oxygenate your water solution keeps DO levels up. Chilling your water solution ensures that your DO levels stay up. Anything below 5 mg/L is very detrimental to plants. Using a DO meter to measure oxygen levels in your water solution keeps your roots permeable and protects them from drowning.

Nutrient Absorption

Each crop has different nutrient requirements and scientists have spent decades refining these formulas. Chilling your water solution will increase nutrient absorption across the entire root zone, no matter what nutrient balance your hydroponic garden needs.

Algae Prevention

The downside of creating the perfect plant growth environment, is that you have created the perfect environment for all plants…including algae. Unfortunately, almost every hydroponic operation encounters algae at some point. If left unchecked, algae spreads quickly, clogs your system, and even becomes toxic to your crop. Algae spores need light, nutrients, water, and warm temperatures in order to thrive. You can’t eliminate light, nutrients, or the presence of water, without damaging your plants. That means using a reservoir chiller on your water solution is the best option for controlling algae growth.

Microbe Balance

Good microbes can help balance out harmful pathogens and fungi from growing in your hydroponic system. Beneficial colonies for specific crops can be purchased and mixed into your water solution at scheduled intervals to inoculate your system and continue to protect it in the future. Keeping your reservoir chilled balances microbial colonies in your favor.

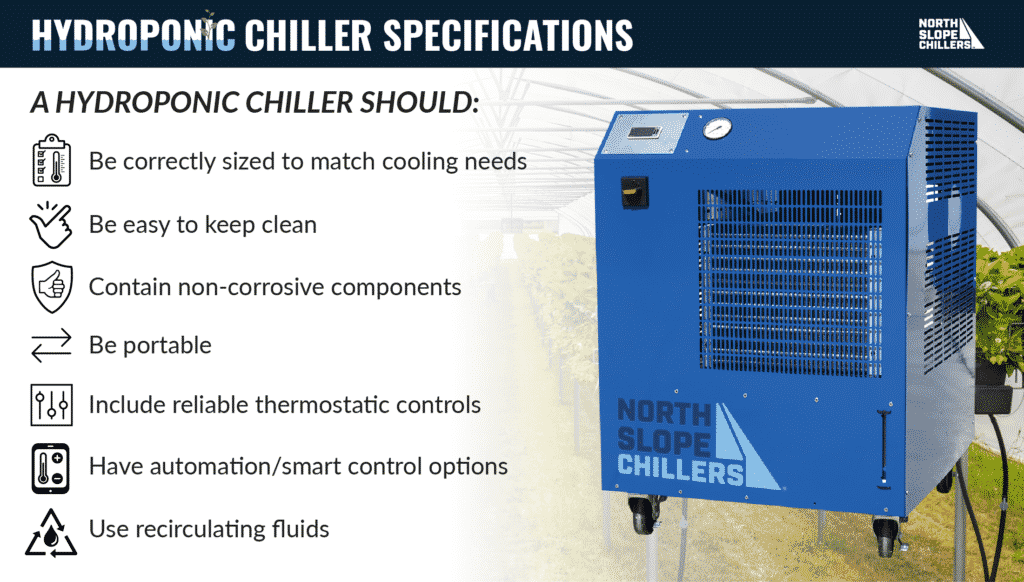

Hydroponic Chiller Specifications

Now we know how crucial it is to chill hydroponic water solutions reservoirs. So what qualities should you look for in a hydroponic reservoir chiller? Let’s take a look at important specifications a chiller should have in order to meet your hydroponic needs.

Correct Sizing

Chillers are typically listed according to BTUs or tons of cooling power (1 ton of cooling power = 12,000 BTUs). Use the following calculation to make sure you select a chiller with enough BTUs to match your requirements:

BTU/hr = Gallons x Temperature Change (°F) x 8.33 / Time (hrs)

First find out how many gallons your reservoir holds. Next, calculate how many degrees your water needs to be chilled. For example, if the water coming out of your hoses is 85°, you need a temperature reduction of 20° F in order to hit 65° F. Lastly, find out how long it takes for your reservoir solution to flow through your set up. Larger hydroponic setups will require more cooling power to make sure the reservoir stays chilled as the water solution returns to the chiller.

Easy to Keep Clean

Greenhouses need to be kept clean in order to preserve the ideal growing environment. It is important to select equipment that is easy to keep clean so you can reduce the chance for mold, mildew, algae, or pests to thrive.

Non Corrosive Components

Be sure to choose a chiller with non-corrosive interior and exterior components. Non corrosive exteriors help with your cleanliness requirements (as mentioned above). Non corrosive interior components won’t leach metal contaminants into your nutrient solution.

Portability

One of the benefits of hydroponic gardening is the flexibility you have to change layouts and add more plants without uprooting your crop. Your hydroponic chiller should not interfere with your ability to adjust your layout as needed. Portable chillers give you the freedom to make changes without disrupting your cooling system.

Reliable Thermostatic Controls

It is important to choose a chiller that allows you to set desired temperature ranges instead of just running all the time. Running a chiller unnecessarily not only drives up your energy costs, but can also overchill your nutrient solution and damage your crops. Select a hydroponic chiller that gives you the ability to cater to your exact temperature needs.

Automation/Smart Control Options

There are a lot of variables to monitor in a hydroponic greenhouse: ph levels, nutrient levels, humidity, air temperature, water solution temperature, crop output, and more. The last thing you need is a reservoir chiller that requires constant babysitting. Choose a chiller that has options for automation and smart temperature controls that relieve stress and free up your valuable time.

Recirculating Fluids

One of the greatest advantages of hydroponic gardening is high yield results for low water consumption. Your watering system carefully recirculates your nutrient solution to and from the reservoir. Therefore you should choose a reservoir chiller that also has the ability to recirculate its internal cooling fluids.

Hydroponic Chilling Solutions from AG-Optimists

Looking for a reservoir chiller that meets all of those requirements? Look no further than AG-Optimists. We specialize in portable industrial chillers with a wide range of cooling capacities that will perfectly match your hydroponic needs.

Portable Industrial Chillers

• Portability for flexible layouts

• Easy to clean powder coated cabinet

• Wide range of sizes to match any grow setup

• Simple to install and use

• Recirculating fluids to save on water use

• Smart temperature control with Beacon

Fluxwrap Cooling Jackets

• Fully insulated against temperature loss

• Multichannel jackets for full cooling coverage

• Wraps around a wide range of reservoir sizes and shapes

• Simple to install, use, and remove for storage

• Easy to clean vinyl exterior

Contact us to find the right hydroponic chiller for your needs at 541-610-6858 or info@ag-optimists-llc.websitepro.hosting